During the recycling and reuse of stainless steel composite panels, it is essential to consider the following aspects to ensure smooth operation and compliance with environmental requirements:

Classification and Identification

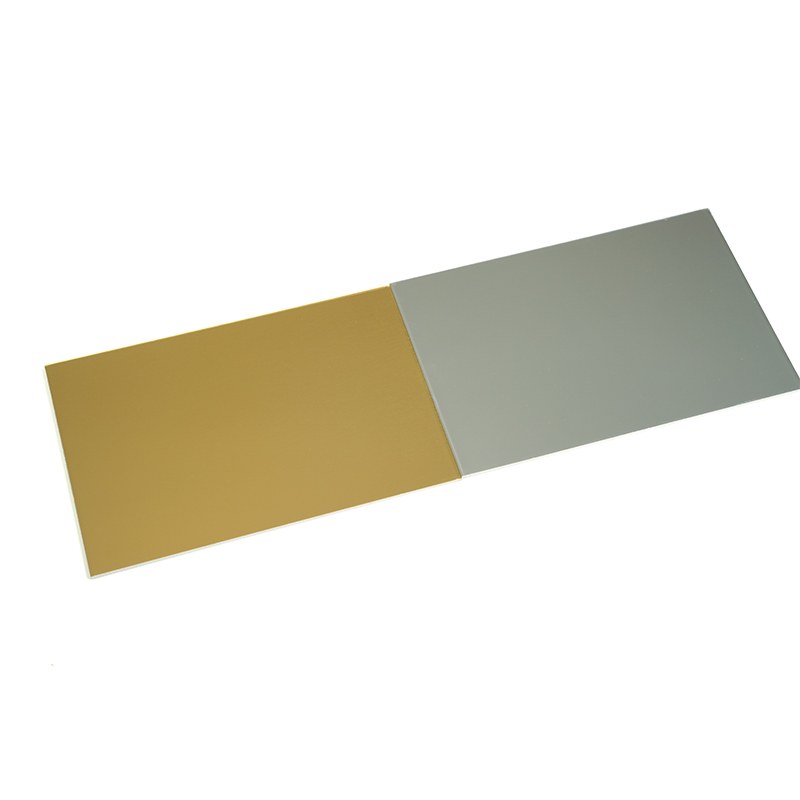

Accurate Classification: When recycling stainless steel composite panels, it is necessary to accurately classify them separately from other types of stainless steel or metal materials to avoid contamination.Material Identification: Since stainless steel composite panels are composed of a stainless steel layer and a base material (such as carbon steel), it is important to identify and distinguish these two materials during recycling for subsequent processing.

Environmental and Safety Considerations

Environmental Treatment: During the recycling and reuse process, environmental protection regulations must be followed to ensure no pollution is caused. Proper treatment of wastewater, exhaust gas, and waste residues should be conducted to meet environmental standards.

Safety Precautions: Operators should wear appropriate protective equipment such as gloves, goggles, and protective clothing to reduce the risk of injury. Extra care should be taken when handling sharp or pointed stainless steel composite panels to prevent cuts or punctures.

Technical Processing

Delamination Treatment: As stainless steel composite panels are composed of multiple layers of materials, delamination treatment may be necessary during recycling to separately recover the stainless steel layer and the base material. Appropriate processes and equipment should be used to ensure effective delamination and minimize material damage.Cleaning and Purification: Recycled stainless steel composite panels may have oil stains, rust, or other contaminants that need to be cleaned and purified to enhance their reuse value.

Reuse and Quality Control

Reuse Methods: After recycling, stainless steel composite panels can be reused based on their material and performance characteristics. For example, they can be reprocessed into new stainless steel composite panels, or the stainless steel layer and base material can be used separately in other fields.Quality Control: Strict quality control is required during the reuse process to ensure that the recycled stainless steel composite panels meet relevant standards and requirements. This includes testing the chemical composition, mechanical properties, and corrosion resistance of the materials.

Market and Economic Benefits

Market Trends: Understanding the market trends and price dynamics of recycled stainless steel composite panels helps in formulating reasonable recycling strategies and pricing.Economic Benefits: Assess the economic benefits of recycling and reusing stainless steel composite panels, including recycling costs, reuse value, and potential environmental benefits.

The recycling and reuse of stainless steel composite panels require attention to classification and identification, environmental and safety considerations, technical processing, reuse and quality control, as well as market and economic benefits. By strictly adhering to relevant regulations and standards and employing appropriate processes and equipment, the recycling and reuse process can proceed smoothly, maximizing resource utilization and economic benefits.