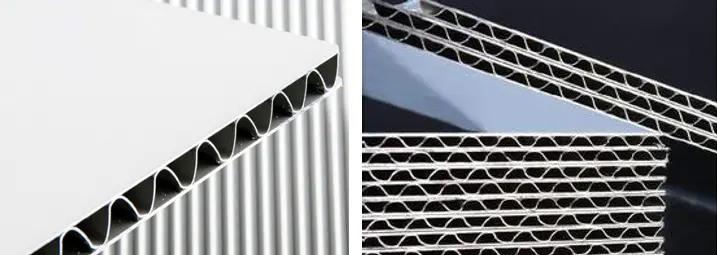

Aluminum corrugated panels are a type of sheet material that consists of multiple layers of aluminum, with a corrugated structure between them. This unique construction enhances the panel’s strength while keeping it lightweight. The layers can be shaped into different forms, with the most common pattern being the “wave” shape. The aluminum sheets are either pre-painted or coated with protective finishes to improve their resistance to weathering, corrosion, and physical damage.

The panels are typically made using a process called roll forming, in which aluminum sheets are fed through rollers that shape them into a corrugated profile. This method allows for precise control over the thickness, length, and shape of the panels, making them adaptable to various design needs.

Key Features of Aluminum Corrugated Panels

Lightweight Yet Strong: One of the most notable features of aluminum corrugated panels is their lightweight nature combined with high strength. The corrugation enhances the material's ability to withstand pressure and impact while maintaining a low weight, which makes them easy to transport and install.

Durability and Longevity: Aluminum is naturally resistant to rust and corrosion, making aluminum corrugated panels highly durable even in harsh environments. Whether exposed to moisture, chemicals, or extreme weather conditions, aluminum corrugated panels retain their structural integrity and appearance over time.

Versatile Design Options: Aluminum panels come in a variety of finishes and colors, making them adaptable to different aesthetic preferences. Whether for a modern commercial building or an industrial warehouse, aluminum corrugated panels can be customized to meet the design requirements.

Energy Efficiency: Some aluminum corrugated panels are coated with reflective finishes or insulating layers that improve energy efficiency. This can help regulate indoor temperatures, reduce energy costs, and improve the sustainability of a building.

Fire Resistance: Aluminum is non-combustible, and the corrugated design provides additional strength, making these panels a safe choice for applications where fire resistance is critical.

Eco-Friendly: Aluminum is a highly recyclable material, and aluminum corrugated panels can be reused or recycled at the end of their life cycle. This contributes to the sustainability of construction projects.

Benefits of Aluminum Corrugated Panels

Cost-Effective: Compared to other materials such as steel or copper, aluminum offers a cost-effective solution without compromising on strength or durability. The lightweight nature of the panels also reduces transportation and installation costs.

Low Maintenance: Aluminum panels require minimal maintenance due to their resistance to corrosion and staining. Routine cleaning with water and mild detergent is typically enough to maintain their appearance.

Speed of Installation: Aluminum corrugated panels are easier to install due to their lightweight nature and pre-fabricated sizes. This can lead to reduced labor costs and faster project completion.

Customization Options: Manufacturers offer a wide range of customization options, including varying thicknesses, colors, finishes, and sizes. This flexibility allows for tailoring the material to suit specific project needs.

Applications of Aluminum Corrugated Panels

Aluminum corrugated panels have a wide range of applications in both the construction and manufacturing industries. Some of the most common uses include:

Roofing: Aluminum corrugated panels are frequently used in commercial and residential roofing. Their weather-resistant properties, combined with their lightweight nature, make them an ideal choice for long-lasting, low-maintenance roofs.

Wall Cladding: These panels are often used as cladding material for building exteriors. The corrugated design provides an appealing aesthetic while offering protection against the elements.

Partitions and Dividers: In industrial settings, aluminum corrugated panels are used as partitions, offering a durable and cost-effective solution for dividing spaces.

Ceiling Panels: Aluminum corrugated panels are also used as ceiling materials in buildings, offering both functional and decorative benefits.

Insulated Panels: In some cases, aluminum corrugated panels are combined

with insulating materials to create insulated panels. These are used for energy-efficient building envelopes, especially in cold climates.

Transportation: Aluminum corrugated panels are used in the manufacturing of trailers, shipping containers, and even as part of the body of certain vehicles due to their strength and lightweight properties.