1. Material Selection

The first step in manufacturing SSCPs is selecting high-quality materials. The stainless steel layers are typically made from grades such as 304 or 316, known for their excellent corrosion resistance and durability. The core material can vary, with options like polyethylene for standard applications or mineral-filled cores for fire-resistant properties.

2. Preparation and Cutting

Once the materials are selected, they undergo preparation. The stainless steel sheets are cut to size using precision cutting techniques, such as laser cutting or water jet cutting. This step ensures that each panel meets specific dimensional requirements and quality standards.

3. Core Bonding

After the stainless steel layers are prepared, the core material is bonded to the stainless steel sheets. This is a critical step that significantly influences the panel's performance. The bonding process typically involves applying a strong adhesive between the stainless steel layers and the core material. This can be done using techniques like heat pressing or cold pressing, depending on the core material used.

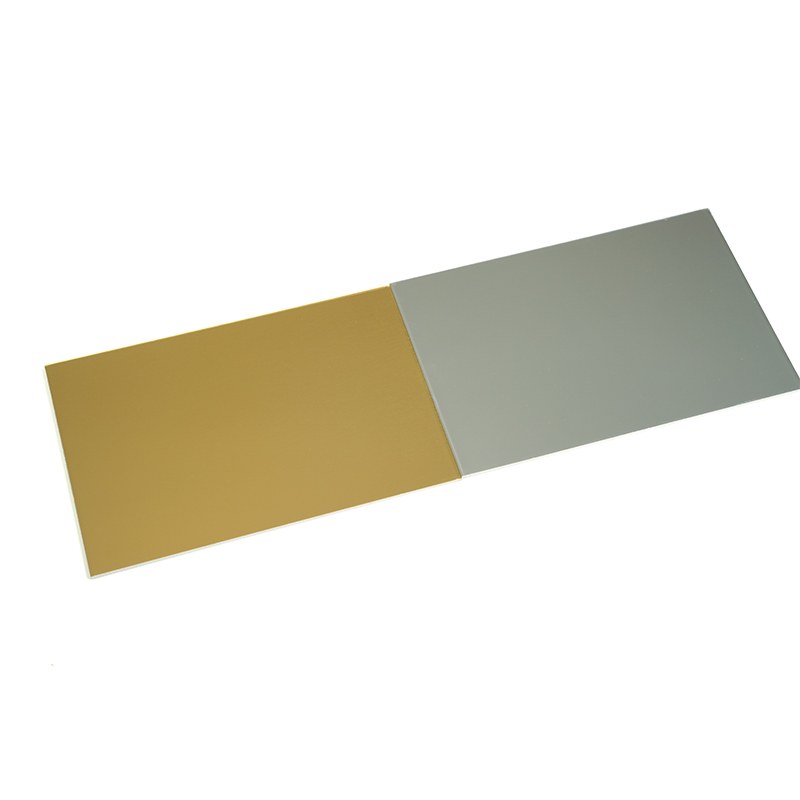

4. Surface Treatment

Once the core is bonded, the panels undergo surface treatment to enhance their appearance and durability. Various finishes can be applied, such as brushed, mirror, or matte finishes. This step not only adds aesthetic value but also increases resistance to scratches, fingerprints, and other surface damage.

5. Quality Control

Quality control is a crucial aspect of the manufacturing process. Each panel is subjected to rigorous testing to ensure it meets industry standards for strength, durability, and appearance. This may include tests for bonding strength, corrosion resistance, and fire resistance, depending on the intended application.

6. Cutting and Shaping

After quality control, the panels are further cut and shaped as needed. This allows for customization to fit specific architectural designs and installation requirements. Precision cutting ensures that edges are clean and that panels can be easily installed without compromising structural integrity.

7. Packaging and Shipping

Finally, the stainless steel composite panels are carefully packaged to prevent damage during transportation. Protective coverings are applied, and the panels are stacked to minimize movement. Efficient packaging and shipping processes are vital to ensure that the panels arrive at their destination in perfect condition.